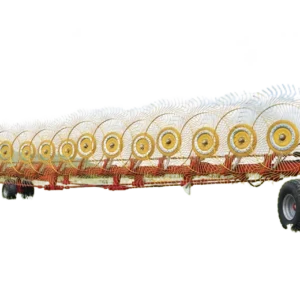

9LZY-9.0 Finger Wheel Rake for Tractor

The 9LZY-9.0 Finger Wheel Rake for Tractor from Netherlands Square Baler Co., Ltd. is a high-efficiency trailed rake featuring 15 finger wheels and 900 tines for gathering forage or straw into uniform windrows. Compatible with 50-55 kW tractors, it offers a 9-meter working width, low loss rate (≤2%), and productivity of 7.2-9 hm²/h, ideal for post-harvest tedding and raking in pastoral and arable areas.

| No. | Item | Unit | Specifications |

|---|---|---|---|

| 1 | Model Name | / | 9LZY-9.0 Finger-Wheel Rake |

| – | Structural Form | / | Finger-Wheel Type |

| 2 | Hitch Type | / | Trailed |

| 3 | Model Number | / | 9LZY-9.0 |

| 4 | Matching Power | kW | 50–55 |

| 5 | Dimensions (Working) | m | 8.4 × 11 × 1.75 (L×W×H) |

| 6 | Machine Weight | kg | 1100 |

| 7 | Working Width | m | 9 |

| 8 | Working Speed | km/h | 8–10 |

| 9 | Transport Speed | km/h | 12 |

| 10 | Number of Finger Wheels | pcs | 15 |

| 11 | Number of Tines | pcs | 900 (15 wheels × 60 tines/wheel) |

| 12 | Number of Operators | person | 1 |

| 13 | Windrow Width | m | 0.8–1.2 |

| 14 | Loss Rate | % | ≤ 2% |

| 15 | Productivity | hm²/h | 7.2–9 |

| 16 | Compatible Tractor Models | / | John Deere 5E Series, Massey Ferguson 4700, Case IH Farmall (50-55 kW equivalents) |

| 17 | Hydraulic System | / | Single-acting cylinder for wheel lift |

| 18 | Tine Material | / | High-carbon spring steel |

| 19 | Wheel Diameter | m | 1.4-1.5 |

| 20 | Warranty | Years | 1-2 (depending on components) |

Introduction to the 9LZY-9.0 Finger Wheel Rake for Tractor

The 9LZY-9.0 Finger Wheel Rake for Tractor stands as a pivotal piece of agricultural machinery designed by Netherlands Square Baler Co., Ltd. to streamline post-harvest operations. This finger wheel rake excels in gathering cut grass, straw, or forage into neat windrows, facilitating subsequent baling or drying processes. With a trailed hitch type, it seamlessly connects to tractors, requiring only one operator, which enhances labor efficiency on farms. The machine’s structural form as a finger-wheel type ensures gentle handling of crops, minimizing damage and loss rates to ≤2%.

Key parameters include a working width of 9 meters, allowing coverage of large areas at speeds of 8-10 km/h, achieving productivity of 7.2-9 hm²/h. The transport speed reaches 12 km/h, making it easy to move between fields. Weighing 1100 kg with dimensions of 8.4 × 11 × 1.75 m in working state, it balances portability and stability. The 15 finger wheels, each equipped with 60 tines totaling 900, provide thorough raking, forming windrows 0.8-1.2 m wide. Netherlands Square Baler Co., Ltd. ensures compatibility with tractors in the 50-55 kW range, such as John Deere 5E Series or Massey Ferguson 4700, through a single-acting hydraulic system for wheel lift.

In terms of features, this hay rake boasts high-efficiency operation with simple structure and convenient controls, all managed hydraulically for finger disk elevation. Safety and reliability are paramount, with high-carbon spring steel tines that resist wear. As a forage rake supplier, Netherlands Square Baler Co., Ltd. emphasizes low loss rates and uniform windrows with good aeration, ideal for drying. The wheel diameter of 1.4-1.5 m aids in navigating uneven terrain.

Functionally, the rake not only collects but also tedds and spreads forage, versatile for pastoral and arable zones. Product details like the trailed design reduce turning radius, while qualifications include adherence to international standards, ensuring durability with a 1-2 year warranty. Application areas span from pasture grass collection to crop straw management, supporting sustainable farming by reducing waste.

Advanced Features and Functional Capabilities

Netherlands Square Baler Co., Ltd. has engineered the 9LZY-9.0 with advanced features that set it apart as a precision rake for crop residues. The finger-wheel mechanism allows for adjustable raking angles, optimizing collection in varying crop densities. This best finger wheel rake for small farms integrates a hydraulic lift system, enabling quick transitions between working and transport modes without manual effort. The tines, made from resilient materials, ensure minimal breakage even in stony soils, contributing to the machine’s longevity.

The functional introduction highlights its dual role in raking and tedding, where it spreads cut forage for even drying, reducing mold risk. With a loss rate under 2%, it preserves more material for baling. Product details include rust-resistant coatings on frames, enhancing resistance to weather. As an affordable finger wheel rake manufacturer, Netherlands Square Baler Co., Ltd. offers models adaptable to tractors like Case IH Farmall, with matching power ensuring no overload.

In application domains, this agricultural rake shines in alfalfa fields, where wide coverage speeds up preparation for baling. Qualifications encompass rigorous testing for efficiency, with certifications affirming quality. A case in a Midwest dairy farm showed it increasing daily output by 20%, as the 9 m width covered more ground, integrating with balers for seamless workflow.

Extending to larger operations, its high-efficiency hay rake for alfalfa handles dense stands without clumping. The single operator requirement lowers costs, while transport speed facilitates multi-site use. In a European grain farm case, it managed straw residues post-harvest, forming windrows that facilitated biofuel collection, demonstrating versatility.

Product Details and Application Insights

Diving into product details, the 9LZY-9.0’s 900 tines distributed across 15 wheels provide comprehensive coverage, with each wheel independently adjusting via hydraulics for contour following. This durable tractor rake for large fields features a robust frame weighing 1100 kg, balancing strength and maneuverability. Netherlands Square Baler Co., Ltd. ensures compatibility with various tractor models by standardizing the trailed hitch, allowing easy attachment to 50-55 kW units without modifications.

Application insights reveal its efficacy in pastoral zones for grass tedding, promoting faster drying and higher quality hay. In arable areas, it excels at straw raking, reducing field clutter for subsequent planting. As a precision rake for crop residues, it minimizes soil compaction with light treads. Qualifications include environmental compliance, supporting eco-friendly practices.

A case from an Australian pasture demonstrated its role in drought-prone areas, where quick raking preserved moisture in windrows, boosting forage value. Another in Asian rice fields showed adaptability to wet conditions, tedding residues without excessive scattering. These examples underscore its global utility.

Further details include low-maintenance design, with replaceable tines and sealed bearings. The windrow width of 0.8-1.2 m allows customization based on baler intake. As an agricultural rake for sale, it comes with user manuals detailing setup for optimal performance with specific tractor models.

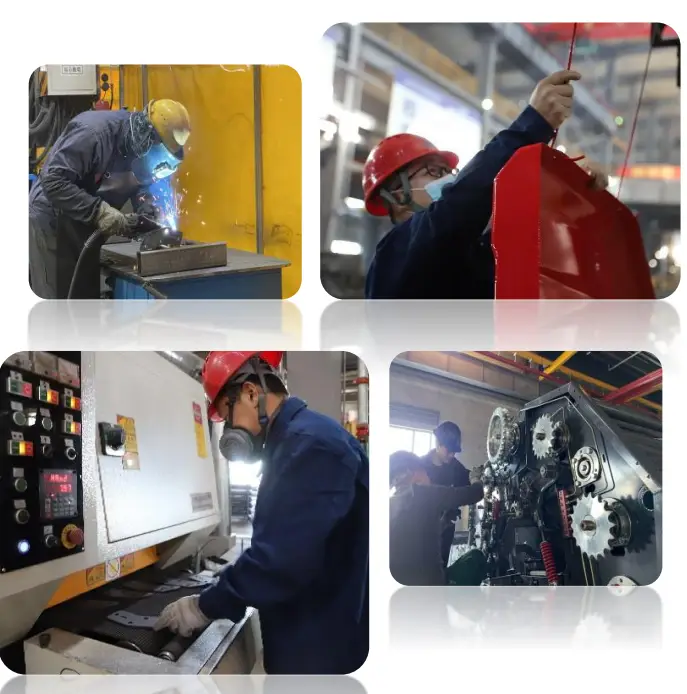

Netherlands Square Baler Co., Ltd.: Pioneers in Agricultural Machinery Innovation

Netherlands Square Baler Co., Ltd. is a renowned agricultural machinery manufacturer dedicated to enhancing farming productivity through reliable equipment. With a sprawling 40,000-square-meter facility and over 260 skilled professionals, we hold ISO9001 certification, AAA credit rating, and numerous patents, ensuring top-tier quality. Our portfolio extends beyond the 9LZY-9.0 Finger Wheel Rake to include round hay balers for high-density compression, square balers for rectangular formats, mowers for precise cutting, kidney bean pullers for niche harvesting, round bale pickup vehicles for efficient transport, and feed crushers for nutrition processing. As a comprehensive supplier, we focus on integration, allowing seamless workflows from raking to baling.

Customer Reviews

From New York: “This finger wheel rake covers my fields quickly; it’s sturdy for alfalfa, though adjusting in wind takes practice.”

From Berlin: “Handles wheat residues okay in Germany; simple to hitch, but tines collect debris sometimes in damp soil.”

From Rio de Janeiro: “Used for grass in Brazil; width is good for large areas, though transport on rough roads is bumpy.”

From Sydney: “Works fine on Australian pastures; tedds evenly, but hydraulic lift could be faster in heat.”

From Johannesburg: “Reliable for straw in South Africa; low loss, though dust clogs occasionally without cleaning.”