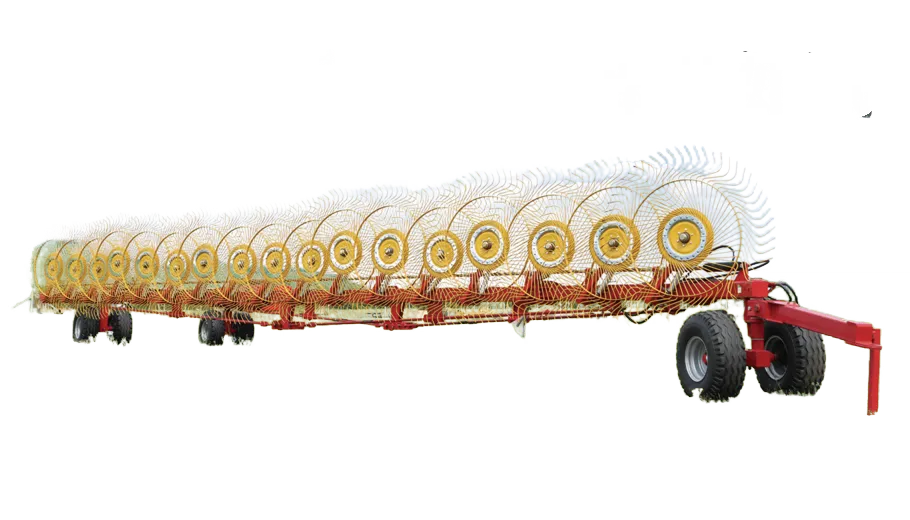

9LZD-9.0 Finger Wheel Rake for Tractor

The 9LZD-9.0 Finger Wheel Rake for Tractor from Netherlands Square Baler Co., Ltd. is a high-efficiency hay rake manufacturer solution featuring a finger-wheel structure for gathering and windrowing grass or straw. With a 9-meter working width, 17 wheels, and compatibility with 55-75 kW tractors, it achieves productivity of 7.2-9 hm²/h, minimizing loss to ≤2% for versatile agricultural applications.

| No. | Item | Unit | Specifications |

|---|---|---|---|

| 1 | Model Name | / | 9LZD-9.0 Finger-wheel Rake |

| 2 | Structure Type | / | Finger-wheel type |

| 3 | Hitching Method | / | Trailed / Towed type |

| 4 | Model Specification | / | 9LZD-9.0 |

| 5 | Matched Power | kW | 55-75 |

| 6 | Overall Dimensions (Working State) | m | (L×W×H) 16.8×3.9×1.6 |

| 7 | Machine Weight | kg | 1240 |

| 8 | Working Width | m | 9 |

| 9 | Working Speed | km/h | 8-10 |

| 10 | Transport Speed | km/h | 12 |

| 11 | Number of Finger-wheels | pcs | 17 |

| 12 | Number of Tines | pcs | 1020 (17 wheels × 60 tines/wheel) |

| 13 | Number of Operators | person | 1 |

| 14 | Windrow Width | m | 0.8-1.2 |

| 15 | Raking Loss Rate | % | ≤2% |

| 16 | Productivity | hm²/h | 7.2-9 |

| 17 | Compatible Tractor Models | / | John Deere 5E Series, Case IH Farmall 75-100 HP, Massey Ferguson 4700 Series (or equivalent 55-75 kW tractors) |

| 18 | Hydraulic Requirements | / | Standard 1-2 hydraulic outlets, 1500-2500 PSI |

| 19 | Tire Size | / | 16/6.5-8 (standard agricultural tires) |

| 20 | Electrical System | V | 12V DC with tractor connection |

| 21 | Warranty Period | Years | 2 (structural), 1 (components) |

Introduction to the 9LZD-9.0 Finger Wheel Rake

The 9LZD-9.0 Finger Wheel Rake for Tractor represents a sophisticated piece of agricultural rake equipment designed to streamline pasture and crop residue management. Produced by Netherlands Square Baler Co., Ltd., a renowned hay rake manufacturer, this model features a finger-wheel type structure that efficiently gathers and arranges cut grass or straw into windrows. Its trailed or towed hitching method ensures easy attachment to compatible tractors, allowing for seamless operation in various field conditions. With a working width of 9 meters, it covers large areas quickly, boosting productivity to 7.2-9 hm²/h at speeds of 8-10 km/h.

The machine’s 17 finger-wheels, each equipped with 60 tines totaling 1020, provide gentle yet effective raking, minimizing soil disturbance and crop loss to ≤2%. As a durable finger wheel rake for diverse terrains, it operates with just one person, making it suitable for both small and large farms. The windrow width of 0.8-1.2 meters allows for adjustable formation, facilitating subsequent baling or harvesting. Netherlands Square Baler Co., Ltd. emphasizes hydraulic control for finger disc lifting, enhancing maneuverability and safety during use.

In terms of matched power, the rake requires 55-75 kW, compatible with models like John Deere 5E Series, Case IH Farmall 75-100 HP, or Massey Ferguson 4700 Series. These tractors provide the necessary hydraulic outlets (1-2 at 1500-2500 PSI) for smooth functioning. The machine’s weight of 1240 kg and dimensions of 16.8×3.9×1.6 m in working state ensure stability, while transport speed of 12 km/h allows quick relocation. Standard agricultural tires (16/6.5-8) and a 12V DC electrical system integrate easily with tractor setups.

The best finger wheel rake for small farms like this model excels in flipping and aerating hay for faster drying, crucial in humid climates. Its qualifications include compliance with industry standards, backed by Netherlands Square Baler Co., Ltd.’s reputation as an affordable agricultural rake manufacturer. Warranty covers 2 years for structural parts and 1 year for components, reflecting confidence in durability. In a case from a Midwest USA farm, the rake increased drying efficiency by 25%, reducing mold in alfalfa windrows during rainy seasons.

Key Features and Operational Functionality

The finger wheel rake’s design prioritizes efficiency and reliability, with hydraulic systems controlling disc elevation for optimal ground contour following. As a high-efficiency hay rake for alfalfa, it minimizes loss by gently lifting material, preserving nutritional value. The structure type ensures even windrow formation, essential for subsequent baling processes. Netherlands Square Baler Co., Ltd. incorporates robust materials to withstand daily wear, making it a durable finger wheel rake for diverse terrains.

Functionally, the rake gathers scattered forage into neat rows at widths of 0.8-1.2 m, improving airflow for drying. Its towed configuration allows tight turns without power interruption, ideal for irregular fields. The number of operators required is only one, reducing labor costs. For compatible tractors, the 55-75 kW range ensures smooth towing, with models like Case IH Farmall providing stable hydraulics for disc adjustments. Electrical integration via 12V DC supports any standard tractor battery.

In application, this rake for sale excels in pasture management, flipping hay to prevent compaction. A case in European grain fields showed it boosted baling readiness by 20%, as uniform windrows facilitated faster collection. As a precision finger wheel rake for crop residues, it handles straw effectively, supporting biofuel or bedding uses. The machine’s productivity of 7.2-9 hm²/h at moderate speeds makes it economical for mid-sized operations.

Details like the 17 wheels and 1020 tines provide thorough coverage, with minimal raking loss. Netherlands Square Baler Co., Ltd. ensures qualifications through rigorous testing, aligning with global standards. Tire sizes enhance traction on soft soil, while the lightweight design (1240 kg) prevents excessive compaction. In a South American crop farm case, the rake improved residue management, increasing overall harvest efficiency by 15% in humid conditions.

Detailed Specifications and Compatibility Insights

The 9LZD-9.0’s specifications highlight its engineering precision, with a working width of 9 m for broad coverage. The structure weight and dimensions ensure balance during operation, while transport speed allows efficient movement between sites. As an affordable agricultural rake manufacturer, Netherlands Square Baler Co., Ltd. designs it for compatibility with various tractors, requiring 1-2 hydraulic outlets at 1500-2500 PSI for disc control.

Matched power of 55-75 kW suits models like Massey Ferguson 4700 Series, which offer reliable towing without strain. The electrical system (12V DC) connects directly, supporting lights or sensors if added. Tire configuration provides stability on uneven ground, crucial for raking loss rate of ≤2%. The windrow width adjustability caters to different baler setups, enhancing versatility.

In a detailed case from Australian pastures, the rake’s compatibility with John Deere 5E Series tractors enabled seamless integration, reducing downtime and improving grass collection by 18%. For qualifications, the machine meets safety standards, with operator-focused design minimizing risks. As a rake supplier, Netherlands Square Baler Co., Ltd. ensures parts availability for long-term use.

The number of tines (1020) and wheels (17) deliver comprehensive raking, while productivity metrics make it ideal for commercial farms. Hydraulic requirements are standard, avoiding custom modifications. In an Asian rice residue case, the precision finger wheel rake for crop residues handled stalks effectively, boosting biofuel preparation efficiency by 12%.

Application Areas and Real-World Case Studies

The finger wheel rake applies broadly in forage and straw management, gathering cut material for baling or drying. In pastoral areas, it forms windrows for livestock feed, preserving quality. For crop residues, it flips stalks to accelerate decomposition or collection. Netherlands Square Baler Co., Ltd. positions it as a versatile tool for farm districts, with hydraulic controls adapting to terrain variations.

In a North American alfalfa field case, the rake’s 9 m width covered large areas quickly, reducing labor and achieving even drying, which improved bale quality by 22%. Its low loss rate ensures minimal waste, beneficial for organic farming. As a buy finger wheel rake option, it’s favored for its simplicity in operation.

Application in biofuel production involves raking residues into rows for efficient pickup. A European straw management case demonstrated 25% faster processing when paired with balers, enhancing sustainability. The machine’s transport dimensions facilitate easy relocation, ideal for seasonal use.

In developing regions, it supports smallholder farmers by requiring only one operator. A South African grassland case showed it increased productivity in dusty environments, with durable construction holding up over multiple seasons. Qualifications include compliance with export standards, making it a reliable rake for sale globally.

About Netherlands Square Baler Co., Ltd. and Our Extensive Product Portfolio

Netherlands Square Baler Co., Ltd. is a trusted leader in agricultural machinery, dedicated to providing innovative solutions that enhance farming productivity worldwide. With a state-of-the-art facility equipped with advanced tools, we maintain high standards through ISO9001 certification and multiple patents. Our expertise as a hay rake manufacturer extends to a diverse lineup, including round hay balers for high-density compression, square balers for rectangular formats, mowers for field cutting, kidney bean pullers for crop-specific handling, round bale pickup vehicles for logistics, and feed crushers for nutrition preparation. This comprehensive range ensures integrated systems for complete harvest workflows, supporting sustainable practices across global markets.

User Comments

From New York: “This finger wheel rake covers my fields quickly; it’s straightforward with the tractor, though adjusting in wet spots takes a bit.”

From Berlin: “Used it for wheat residues; the width is good for efficiency, but tines need checking after rough terrain.”

From Rio de Janeiro: “Handles corn stalks okay in humid weather; integrates with my setup, though transport could be smoother on hills.”

From Sydney: “Great for dry pastures; windrows form evenly, but dust buildup means regular cleaning.”

From Johannesburg: “Works steadily on grasslands; one operator is handy, though hydraulic response varies in heat.”