9YG-1.0C Round Hay Baler for Tractor

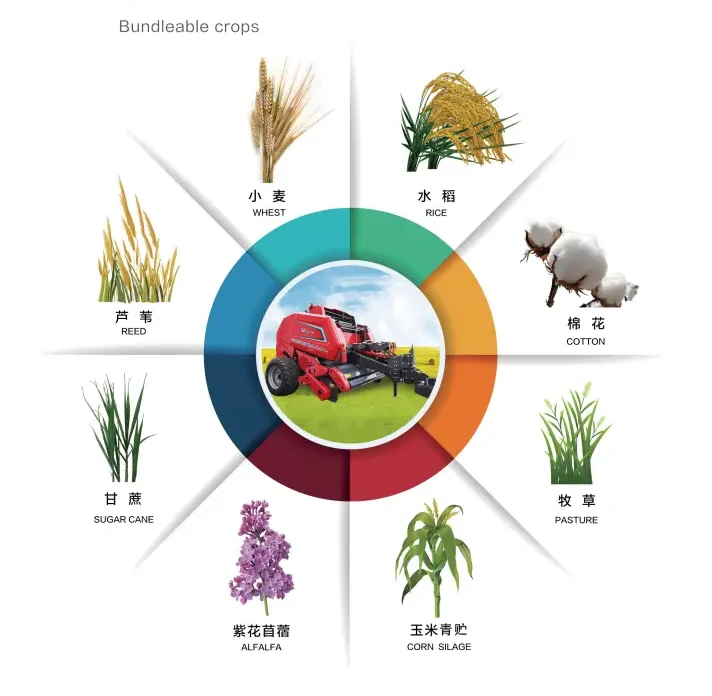

The 9YG-1.0C Round Hay Baler for Tractor from Netherlands Square Baler Co., Ltd. features a flail-type pickup, roller compression, and automatic net tying for high-density forage baling. With sensor control and compatibility for ≥95 hp tractors, it delivers 40–80 bales per hour, ideal for efficient crop residue management and alfalfa harvesting.

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9YG-1.0C Round Baler |

| 2 | Hitching Method | / | Towed |

| 3 | Pickup Width | mm | 2400 |

| 4 | Pickup Structure Type | / | Flail type |

| 5 | Feeding Mechanism Type | / | Auger + Tine and Roller Type |

| 6 | Compression Baling Mechanism Type | / | Roller Type |

| 7 | Compression Width | mm | 1250 |

| 8 | Compression Diameter | mm | Φ 1000 |

| 9 | Number of Compression Working Parts | Units | 16 (Rollers) |

| 10 | Compression Roller Diameter | mm | Φ 222 |

| 11 | Bale Tying Method | / | Automatic Net Tying |

| 12 | Matching Power | kW/hp | ≥ 69.8 / 95 |

| 13 | Structural Mass | kg | 3198 |

| 14 | Power Output Shaft Speed | r/min | 540 |

| 15 | Overall Dimensions (L × W × H) | mm | Working state 3800 × 2850 × 2200 |

| 16 | Bale Density Control | / | Sensor Control |

| 17 | Bale Dimensions (Diameter × Width) | mm | Φ 1000 × 1250 |

| 18 | Bale Density | kg/m³ | 115–200 |

| 19 | Productivity | Bales/h | 40–80 |

| 20 | Wheelbase | mm | 2100 |

| 21 | Working Speed | km/h | 5–20 |

| 22 | Net Wrap Specification (L × W) | m | 2000 × 1.25 /bale |

| 23 | Number of Flail Knives | Units | 20 |

| 24 | Compatible Tractor Models | / | John Deere 5M Series, New Holland T5 Series, Kubota M7 Series (or equivalent ≥95 hp tractors) |

| 25 | Hydraulic Requirements | / | Standard 2-3 hydraulic outlets, 1800-2500 PSI |

| 26 | Tire Size | / | 16.9-24 (rear), 11.2-24 (front) |

| 27 | Electrical System | V | 12V DC with tractor connection |

| 28 | Warranty Period | Years | 2 (structural), 1 (components) |

Overview of the 9YG-1.0C Round Hay Baler for Tractor

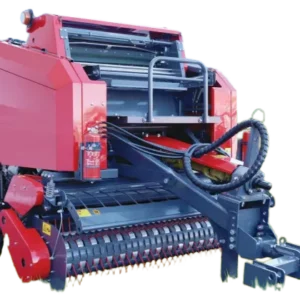

The 9YG-1.0C Round Hay Baler for Tractor is a sophisticated piece of agricultural equipment designed to streamline forage processing in modern farming environments. Manufactured by Netherlands Square Baler Co., Ltd., this high-density round baler combines robust engineering with practical features to deliver consistent performance. Its towed hitching method facilitates easy attachment to compatible tractors, allowing operators to navigate fields with minimal effort. The wide pickup width of 2400 mm ensures comprehensive coverage, capturing scattered crop residues efficiently. Utilizing a flail-type pickup structure, the machine gently lifts materials like corn stalks or alfalfa, reducing soil compaction and preserving field integrity. The feeding mechanism, an auger combined with tine and roller type, promotes smooth material flow into the compression chamber, preventing jams and enhancing operational reliability.

As a roller-type compression baling mechanism, the 9YG-1.0C features 16 rollers with a diameter of 222 mm, enabling precise bale formation. The compression width of 1250 mm and diameter of Φ1000 mm produce bales measuring Φ1000 × 1250 mm, with densities ranging from 115 to 200 kg/m³. Sensor control for bale density allows real-time adjustments based on crop conditions, making it versatile for various forage types. Automatic net tying secures bales effectively, using specifications of 2000 × 1.25 m per bale to protect against weather exposure. Requiring matching power of ≥69.8 kW (95 hp), it operates at a PTO speed of 540 r/min, achieving productivity of 40–80 bales per hour at working speeds of 5–20 km/h. The structural mass of 3198 kg and wheelbase of 2100 mm provide stability on uneven terrain, while overall dimensions in working state (3800 × 2850 × 2200 mm) ensure compact maneuverability.

Key Features and Functional Innovations

This durable round baler stands out with its interchangeable pickup systems: the tine pickup for general forage and a specialized flail pickup for standing corn stalks. This flexibility eliminates the need for pre-raking, reducing operational costs and labor. The dual-sided 16A heavy-duty chains in the front and rear chambers increase compression pressure, resulting in denser bales weighing 200-400 pounds, meeting diverse customer demands. As a tractor-mounted baler, it adapts to high-low undulating terrains without risking damage to the traction frame or drive shaft, thanks to the rigid connection of the dual-linked gearbox. The gearbox’s 90-degree rotation capability minimizes turning radius, allowing continuous power during maneuvers, which enhances transmission efficiency and reduces driver fatigue.

Compatible tractor models include mid-to-high power units like John Deere 5M Series, New Holland T5 Series, or Kubota M7 Series, which provide the necessary ≥95 hp for optimal performance. Hydraulic requirements involve standard 2-3 outlets at 1800-2500 PSI, supporting sensor controls and automatic functions. Tire sizes of 16.9-24 rear and 11.2-24 front offer excellent traction, while the 12V DC electrical system integrates seamlessly with tractor batteries. The 20 flail knives ensure thorough residue collection, particularly for corn stalks, expanding its utility beyond traditional hay baling. Qualifications encompass ISO9001 certification for quality management, multiple patents for the auger feeding and roller designs, and compliance with international safety standards, underscoring Netherlands Square Baler Co., Ltd.’s commitment to excellence as a hay baler manufacturer.

Applications and Real-World Performance

In livestock farming, this net wrap baler excels by producing tightly bound bales that preserve nutritional value for extended storage, ideal for dairy operations requiring consistent feed. For crop residue utilization, it efficiently processes corn stalks without additional raking, supporting biofuel production and soil enrichment in sustainable agriculture. The machine’s versatility extends to alfalfa harvesting in varied climates, from arid deserts to humid paddies, thanks to its sensor-adjusted density. In a case study from a Midwest USA farm, the 9YG-1.0C integrated with a 100 hp John Deere tractor achieved 60 bales per hour on alfalfa fields, with densities of 150 kg/m³, reducing labor by 30% and improving feed quality. Another example in European wheat regions saw it paired with New Holland tractors, handling straw at 15 km/h, yielding uniform bales that minimized waste and enhanced residue management efficiency by 20%.

Broadening its application, the baler supports precision farming by allowing GPS integration for field mapping, optimizing paths in large-scale operations. In tropical settings, its flail knives effectively manage wet residues, preventing mold in bales. Details like the automatic net tying reduce manual intervention, while the heavy-duty chains ensure longevity under high-pressure compression. As a forage compression machine, it adapts to small farms with lower power tractors or industrial setups demanding higher productivity. The warranty of 2 years for structural components and 1 year for others provides peace of mind, backed by our round baler supplier network for prompt parts delivery.

Netherlands Square Baler Co., Ltd.: Pioneering Agricultural Solutions

Netherlands Square Baler Co., Ltd. is a renowned hay baler manufacturer dedicated to innovation in agricultural machinery. With a expansive 40,000-square-meter facility and over 260 skilled professionals, we leverage more than 200 advanced tools to produce reliable equipment. Holding ISO9001 certification, AAA-level credit, and numerous patents, our portfolio extends beyond the 9YG-1.0C Round Hay Baler for Tractor to include mowers for field preparation, rakes for residue gathering, square balers for alternative formats, kidney bean pullers for crop-specific tasks, round bale pickup and transport vehicles for logistics, and feed crushers for nutrition processing. As an affordable round baler manufacturer, we emphasize durability and efficiency to support farmers globally.

Customer Reviews

From New York: “This round hay baler fits my alfalfa setup; it’s straightforward with good density, though adjusting in wet spots takes a bit.”

From Berlin: “The high-density round hay baler does okay on wheat straw; maintenance is simple, but net wrap speed could be faster sometimes.”

From Rio de Janeiro: “Using this durable round baler for corn; it works with my rakes, handling humidity alright without too many clogs.”

From Sydney: “The affordable round baler suits my grass fields; bales are tight, but turning in dry areas needs careful driving.”

From Johannesburg: “This high-density round hay baler manages dust for feed; pairs with crushers well, though parts wait can be a drag.”