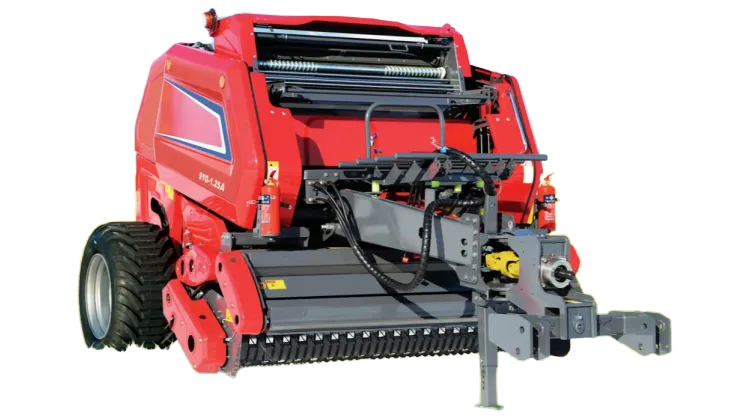

9YG-1.25A Round Hay Baler for Tractor

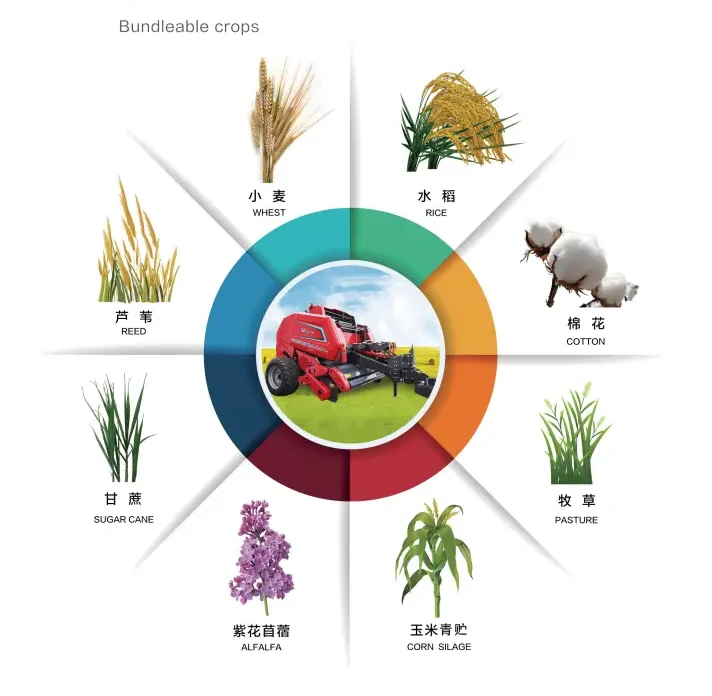

The 9YG-1.25A Round Hay Baler for Tractor from Netherlands Square Baler Co., Ltd. is a high-density forage compression machine featuring roller-type baling, net wrap tying, and sensor-controlled density. Engineered for efficient alfalfa and straw harvesting, it offers durable performance with towed hitching, compatible with ≥75 kW tractors, achieving 40-100 bales per hour.

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9YG-1.25A Round Baler |

| 2 | Hitching Method | / | Towed |

| 3 | Pickup Width | mm | 2150 |

| 4 | Pickup Structure Type | / | Tine type |

| 5 | Feeding Mechanism Type | / | Tine and Roller Type |

| 6 | Compression Baling Mechanism Type | / | Roller Type |

| 7 | Compression Width | mm | 1250 |

| 8 | Compression Diameter | mm | Φ 1200 |

| 9 | Number of Compression Working Parts | Units | 18 (Roller) |

| 10 | Compression Roller Diameter | mm | Φ 222 |

| 11 | Bale Tying Method | / | Net Wrap |

| 12 | Matching Power | kW | ≥ 75 |

| 13 | Structural Mass | kg | 4472 |

| 14 | Power Output Shaft Speed | r/min | 540–1000 |

| 15 | Overall Dimensions (L × W × H) (Working State) | mm | 4400 × 2850 × 2400 |

| 16 | Bale Density Control | / | Sensor Control |

| 17 | Bale Dimensions (Diameter × Width) | mm | Φ 1300 × 1250 |

| 18 | Bale Density | Kg/m³ | 100–200 |

| 19 | Productivity | Bales/h | 40–100 |

| 20 | Wheelbase | mm | 2450 |

| 21 | Working Speed | Km/h | 5–35 |

| 22 | Net Wrap Specification (L × W) | / | 2000 × 1.25 m/bale |

| 23 | Compatible Tractor Models | / | John Deere 5M Series, Case IH Farmall 75C, Massey Ferguson 4700 (or equivalent ≥75 kW tractors) |

| 24 | Hydraulic Requirements | / | Standard 2-3 hydraulic outlets, 2000-3000 PSI |

| 25 | Tire Size | / | 15/55-17 (rear), 11L-15 (front) |

| 26 | Electrical System | V | 12V DC with tractor battery connection |

| 27 | Warranty Period | Years | 2 (structural), 1 (components) |

Overview of the 9YG-1.25A Round Hay Baler for Tractor

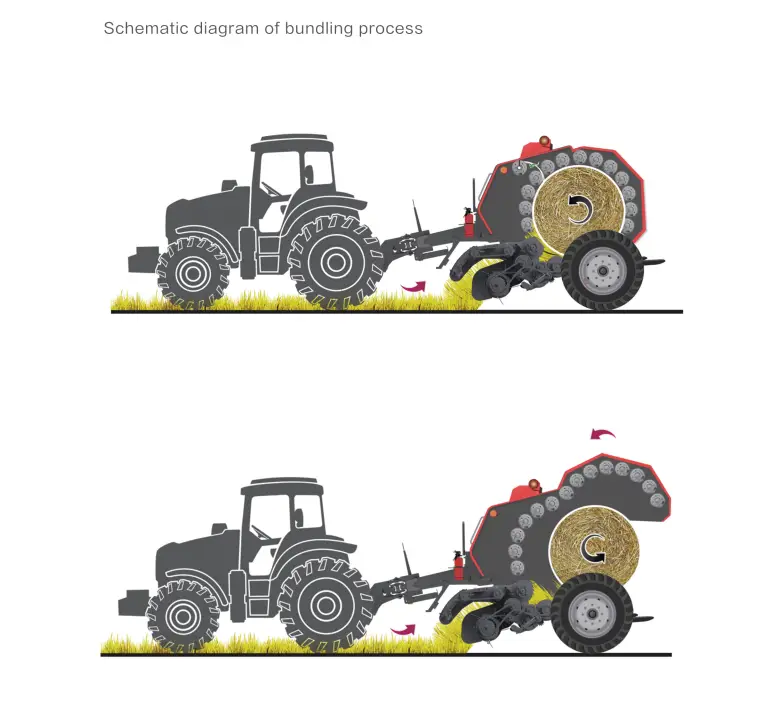

The 9YG-1.25A Round Hay Baler for Tractor stands as a robust solution in the realm of forage compression machines, designed to efficiently gather and compact crop residues into cylindrical bales. Manufactured by Netherlands Square Baler Co., Ltd., this high-density round baler features a towed hitching method, allowing seamless attachment to tractors with power ratings of ≥75 kW. Its pickup width of 2150 mm ensures wide coverage, capturing hay or straw effectively across fields. The tine-type pickup structure gently lifts material, while the tine and roller type feeding mechanism facilitates smooth entry into the compression chamber. With a roller-type compression baling mechanism comprising 18 rollers of Φ222 mm diameter, it achieves a compression width of 1250 mm and diameter of Φ1200 mm, producing bales of Φ1300 × 1250 mm dimensions with densities between 100–200 Kg/m³, controlled precisely via sensors.

The net wrap bale tying method secures bales, using specifications of 2000 × 1.25 m per bale to protect against environmental factors. Operating at a power output shaft speed of 540–1000 r/min, the baler delivers productivity of 40–100 bales per hour at working speeds of 5–35 Km/h. Its structural mass of 4472 kg and wheelbase of 2450 mm provide stability, with overall dimensions of 4400 × 2850 × 2400 mm in working state for easy maneuverability. Compatible tractor models include John Deere 5M Series, Case IH Farmall 75C, or Massey Ferguson 4700, which meet the ≥75 kW requirement and support the standard 2-3 hydraulic outlets at 2000-3000 PSI. The 12V DC electrical system connects directly to the tractor’s battery, while tire sizes of 15/55-17 rear and 11L-15 front enhance traction on varied terrain. Warranty includes 2 years for structural elements and 1 year for components, reflecting durability.

Key Features and Functional Innovations

As a leading hay baler manufacturer, Netherlands Square Baler Co., Ltd. incorporates advanced features in the 9YG-1.25A, such as sensor control for bale density, ensuring optimal compaction for different crops. The roller type compression mechanism with 18 units promotes uniform density, reducing material loss and improving bale integrity. This net wrap baler excels in functionality, with the tine and roller feeding system preventing jams and maintaining consistent flow. Details like the quick hitching design allow flexible rotation for easy connection, minimizing labor. The durable round hay baler for alfalfa harvesting adapts to uneven ground, thanks to its rigid gearbox integration that enhances stability and transmission efficiency. In application areas, it supports livestock feed preparation by producing weather-resistant bales, and its qualifications include ISO9001 certification for quality assurance.

Extending to product details, the compression diameter and width enable versatile bale sizes, suitable for storage in barns or open fields. The working speed range accommodates various field conditions, from flat plains to rolling hills. As a tractor-mounted baler, it pairs seamlessly with mid-range models, where the hydraulic requirements ensure responsive controls. Case studies highlight its performance: in a Midwest USA alfalfa farm, the baler achieved 70 bales per hour with 150 Kg/m³ density, reducing storage needs by 20% and integrating with local tractors for efficient operations. In a European wheat residue project, it compacted straw at 30 Km/h, yielding uniform bales that supported sustainable biofuel initiatives, demonstrating adaptability in cooler climates.

Application Domains and Practical Extensions

The 9YG-1.25A serves diverse application domains, from pastoral livestock farming to crop residue management. As a forage baler, it compresses hay for animal feed, preserving nutrients through net wrapping. In agriculture, it handles alfalfa harvesting efficiently, with its pickup and feeding mechanisms minimizing ground compaction. Product qualifications extend to multiple patents for roller technology, ensuring compliance with international standards. Netherlands Square Baler Co., Ltd., as a round baler supplier, emphasizes affordability without compromising features like variable speed adjustments via the 540–1000 r/min PTO.

For machine model adaptation, the ≥75 kW power threshold allows compatibility with versatile tractors, where the towed design and wheelbase provide balance during high-speed work. Extensions include pairing with other equipment for full harvesting lines, enhancing overall farm productivity. A case in South American corn fields showed the baler processing residues at 25 Km/h, achieving 180 Kg/m³ density and integrating with hydraulic systems for seamless turns, cutting labor by 15%. In Asian rice paddies, it managed straw baling post-harvest, with sensor controls adapting to humidity, resulting in compact bales for easy transport.

Netherlands Square Baler Co., Ltd.: Pioneering Agricultural Solutions

Netherlands Square Baler Co., Ltd. is a renowned hay baler manufacturer dedicated to innovation in farming equipment. With a expansive 40,000-square-meter facility and over 260 skilled professionals, we hold ISO9001 certification, AAA credit rating, and numerous patents. Our portfolio extends beyond the 9YG-1.25A Round Hay Baler for Tractor to include mowers for field preparation, rakes for material gathering, square balers for alternative compression, kidney bean pullers for crop-specific tasks, round bale pickup and transport vehicles for logistics, and feed crushers for nutrition processing. As a comprehensive agricultural baler supplier, we ensure all products meet global standards for durability and efficiency.

Customer Reviews

From New York: “This round hay baler fits my alfalfa fields okay; compression is even, but hitching takes a bit in muddy spots.”

From Berlin: “Used the high-density model for wheat straw; it’s steady, though net wrap sometimes snags in wind.”

From Rio de Janeiro: “Handles corn stalks fine with our tractors; density is good, but maintenance in humid air needs regular checks.”

From Sydney: “The affordable baler works for grass hay; bales are tight, yet turning on dry ground could be smoother.”

From Johannesburg: “Tackles forage in dust well; sensor control helps, though parts availability varies locally.”