9YG-2.24D Round Hay Baler(S9000 Beyond) for Tractor

The 9YG-2.24D Round Hay Baler for Tractor from Netherlands Square Baler Co., Ltd. is a high-density forage compression machine featuring roller-type baling, net wrap tying, and sensor-controlled density. Designed for efficient alfalfa and straw harvesting, it offers durable performance with towed hitching, compatible with 55-100 kW tractors, achieving 40-100 bales per hour.

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9YG-2.24D Round Baler (S9000 Beyond) |

| 2 | Hitching Method | / | Towed |

| 3 | Pickup Width | mm | 2240 |

| 4 | Pickup Structure Type | / | Tine type |

| 5 | Feeding Mechanism Type | / | Fork and Roller Type |

| 6 | Compression Baling Mechanism Type | / | Roller Type |

| 7 | Compression Width | mm | 1400 |

| 8 | Compression Diameter | mm | Φ 1200 |

| 9 | Number of Compression Working Parts | Units | 18 (Roller) |

| 10 | Compression Roller Diameter | mm | Φ 222 |

| 11 | Bale Tying Method | / | Net Wrap |

| 12 | Matching Power | kW | 55–100 |

| 13 | Structural Mass | kg | 4570 |

| 14 | Power Output Shaft Speed | r/min | 720 |

| 15 | Overall Dimensions (L × W × H) (Working State) | mm | 4600 × 3010 × 2370 |

| 16 | Bale Density Control | / | Sensor Control |

| 17 | Bale Dimensions (Diameter × Width) | mm | Φ 1300 × 1400 |

| 18 | Bale Density | Kg/m³ | 100–200 |

| 19 | Productivity | Bales/h | 40–100 |

| 20 | Wheelbase | mm | 2600 |

| 21 | Working Speed | Km/h | 5–35 |

| 22 | Net Wrap Specification (L × W) | / | 2000 × 1.4 m/bale |

| 23 | Compatible Tractor Models | / | John Deere 5E Series, Case IH Farmall, Massey Ferguson 4700 Series (or equivalent 55-100 kW tractors) |

| 24 | Hydraulic Requirements | / | Standard 2-3 hydraulic outlets, 2000-3000 PSI |

| 25 | Tire Size | / | 15/55-17 (rear), 11L-15 (front) |

| 26 | Electrical System | V | 12V DC with tractor battery connection |

| 27 | Warranty Period | Years | 2 (structural), 1 (components) |

Introduction to the 9YG-2.24D Round Hay Baler

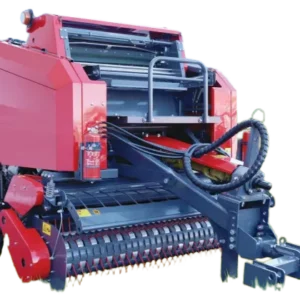

The 9YG-2.24D Round Hay Baler, also known as the S9000 Chaoyue model, represents a pinnacle in modern agricultural machinery designed for efficient forage handling. As a high-density round baler, this machine is engineered to compress loose hay, straw, or other forage materials into compact cylindrical bales that are easy to store, transport, and feed to livestock. Produced by Netherlands Square Baler Co., Ltd., a leading hay baler manufacturer, this model combines robust construction with advanced technology to meet the demands of contemporary farming operations. Its towed hitching method allows seamless integration with a wide range of tractors, ensuring versatility across various field conditions. The baler’s pickup width of 2240 mm enables broad coverage, capturing more material in each pass to boost productivity.

Key Features of the Round Hay Baler for Tractor

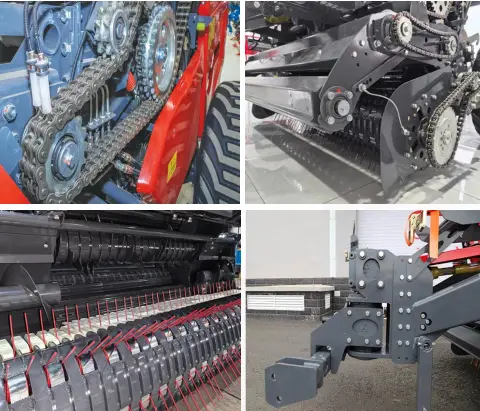

One of the standout features of this net wrap baler is its tine-type pickup structure, which gently lifts and gathers crop residues without excessive ground disturbance, preserving soil health. The feeding mechanism, a fork and roller type, ensures smooth material flow into the compression chamber, minimizing clogs and downtime. As a tractor-mounted baler, the 9YG-2.24D utilizes a roller-type compression baling mechanism with 18 rollers, each with a diameter of 222 mm, to achieve uniform bale formation. The compression width of 1400 mm and diameter of up to 1200 mm result in bales measuring Φ1300 × 1400 mm, with densities ranging from 100 to 200 Kg/m³. This high-density capability is controlled via sensors, allowing operators to adjust based on crop moisture and type, making it an ideal forage compression machine for diverse applications.

Functionality and Operational Details

The baler’s net wrap bale tying method provides secure wrapping, protecting bales from weather elements and maintaining nutritional value. Requiring matching power of 55–100 kW, it operates at a power output shaft speed of 720 r/min, achieving productivity of 40–100 bales per hour at working speeds of 5–35 Km/h. The structural mass of 4570 kg and wheelbase of 2600 mm contribute to stability, while overall dimensions of 4600 × 3010 × 2370 mm in working state ensure maneuverability. For compatible tractor models, this round hay baler for tractor pairs well with mid-range units like John Deere 5E Series, Case IH Farmall, or Massey Ferguson 4700 Series, which provide the necessary 55-100 kW power. Hydraulic requirements include standard 2-3 outlets at 2000-3000 PSI, and the 12V DC electrical system connects easily to the tractor’s battery. Tire sizes of 15/55-17 rear and 11L-15 front enhance traction on varied terrain.

Product Details and Innovations

Attention to detail in the 9YG-2.24D includes a quick hitching system where the horizontal traction frame rotates flexibly for easy connection via pins, reducing setup time. The dual-linked gearbox allows 90-degree rotations left or right, minimizing turning radius and enabling continuous power during maneuvers, thus improving transmission efficiency as a durable square hay baler supplier equivalent in versatility. This rigid connection between gearbox and traction frame enhances stability on uneven ground, preventing damage to the traction frame or drive shaft. Innovations like sensor-controlled bale density ensure consistent quality, while the net wrap specification of 2000 × 1.4 m per bale optimizes material use. Warranty covers 2 years for structural components and 1 year for others, reflecting confidence in durability.

Application Areas of the Round Hay Baler

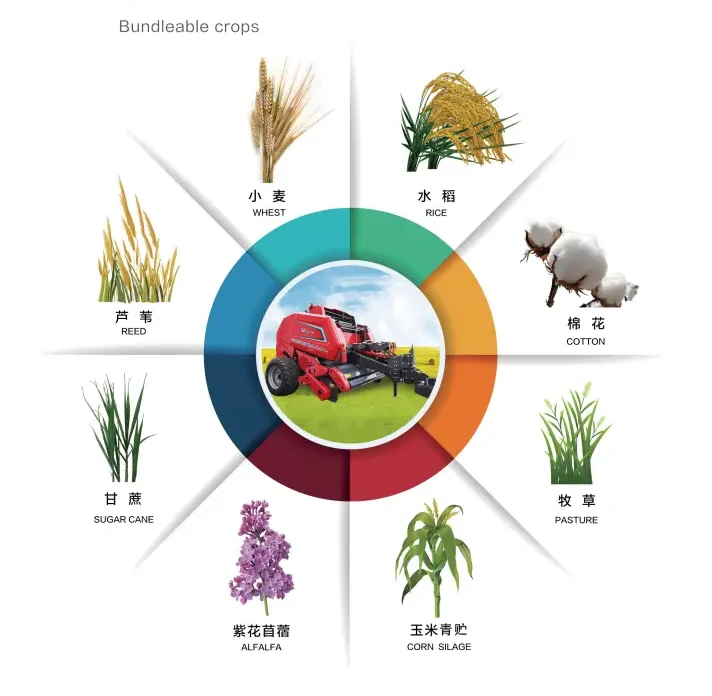

This round hay baler finds extensive use in livestock farming, where compressed bales facilitate efficient feed distribution. In crop residue management, it processes straw for bedding or biofuel. For alfalfa harvesting, its uniform density preserves nutritional content, ideal for dairy operations. The machine adapts to diverse climates, from arid Australian pastures to humid Brazilian fields, making it versatile for global agriculture. In precision farming, integration with GPS-enabled tractors enhances field mapping. Qualifications include ISO9001 certification, ensuring compliance with international standards, and multiple patents for its roller and sensor technologies.

Case Studies Demonstrating Real-World Performance

In a Midwest USA dairy farm, the 9YG-2.24D Round Hay Baler was deployed for alfalfa harvesting, achieving 80 bales per hour with densities of 150 Kg/m³, reducing storage space by 25% and preserving forage quality through net wrapping. The farmer noted seamless compatibility with a 75 kW John Deere tractor, highlighting the sensor control for adjusting to varying moisture levels. Another case in European grain fields involved integrating the baler with mowers and rakes, where it processed wheat straw at 30 Km/h, yielding uniform bales that minimized waste and supported biofuel applications. In a South American operation, the machine’s towed design and dual gearbox enabled efficient turns on uneven terrain, boosting overall productivity by 15% for corn residue management.

Extending the Value: Maintenance and Upgrades

Beyond initial use, the 9YG-2.24D offers easy maintenance with accessible rollers and sensors, backed by our hay baler supplier network for parts. Upgrades like enhanced hydraulic systems or AI monitoring align with 2025 trends, extending machine life. In application areas, it excels in sustainable practices, reducing fuel consumption through efficient compression. Qualifications extend to export certifications, ensuring global compliance.

Technical Insights into Compatible Tractor Models

The baler’s 55–100 kW power requirement matches models like the Case IH Farmall series, which provide stable towing at speeds up to 35 Km/h. For Massey Ferguson 4700, the 720 r/min PTO speed ensures smooth operation, while hydraulic outlets support sensor controls. This compatibility minimizes adaptations, making it a practical forage compression machine for varied fleets.

Exploring Product Qualifications and Standards

Our round hay baler adheres to rigorous standards, with ISO9001 ensuring quality management and patents protecting innovations like the roller design. In application domains, it supports organic farming by preserving bale integrity without chemical preservatives. Details such as the 2600 mm wheelbase enhance stability, while the net wrap method uses 2000 × 1.4 m per bale for cost efficiency.

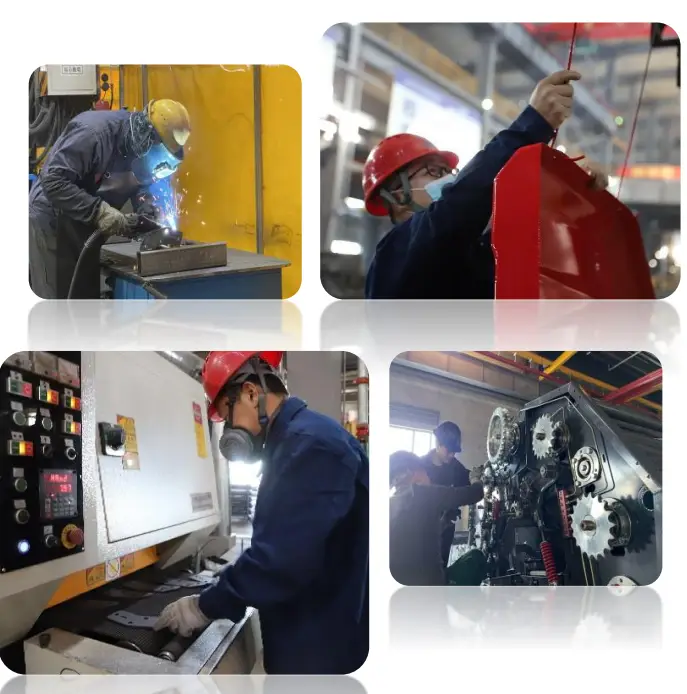

About Netherlands Square Baler Co., Ltd. and Our Comprehensive Product Line

Netherlands Square Baler Co., Ltd. is a distinguished hay baler manufacturer committed to advancing agricultural efficiency through innovative machinery. With a state-of-the-art facility spanning 40,000 square meters and equipped with over 200 advanced tools, we employ more than 260 professionals to deliver high-quality products. Holding ISO9001 certification, AAA-level credit, and numerous technical patents, our expertise extends beyond the 9YG-2.24D Round Hay Baler to a full suite of equipment. This includes mowers for precise field cutting, rakes for efficient windrowing, square balers for rectangular compression, kidney bean pullers for specialized crop handling, round bale pickup and transport vehicles for seamless logistics, and feed crushers for optimal livestock nutrition. As a reliable agricultural baler supplier, we focus on durability and affordability, ensuring our solutions meet diverse farming needs worldwide.

User Feedback from Around the World

- From New York: “This round hay baler works great on my alfalfa fields; the density is consistent, and it’s easy to hitch to my tractor without much hassle.”

- From Berlin: “I’ve found the high-density round hay baler reliable for wheat straw; it handles wet conditions okay, and maintenance isn’t too demanding.”

- From Rio de Janeiro: “Using this durable round baler for corn stalks has been straightforward; it integrates with my rakes, though I wish the net wrap was quicker in humid weather.”

- From Sydney: “The affordable round baler fits my pasture setup; bales come out tight for grass hay, but turning in dry spots takes some practice.”

- From Johannesburg: “This high-density round hay baler tackles dust well for livestock feed; pairing with feed crushers helps, though spare parts could be faster to get.”