9YG-2.24D Round Hay Baler(S9000 Classic) for Tractor

The 9YG-2.24D Round Hay Baler (S9000 Classic) for Tractor from Netherlands Square Baler Co., Ltd. is a durable, high-density net wrap baler designed for efficient forage compression. Featuring roller-type baling with sensor control, it produces uniform bales (Φ1300 × 1400 mm, 100–200 Kg/m³) at 40–100 bales per hour. Compatible with 55–100 kW tractors like John Deere 5E Series, it includes advanced traction and hydraulic systems for smooth operation on varied terrain.

| No. | Item | Unit | Specification |

|---|---|---|---|

| 1 | Model Name | / | 9YG-2.24D Round Baler (S9000 Classic) |

| 2 | Hitching Method | / | Towed |

| 3 | Pickup Width | mm | 2240 |

| 4 | Pickup Structure Type | / | Tine type |

| 5 | Feeding Mechanism Type | / | Fork and Roller Type |

| 6 | Compression Baling Mechanism Type | / | Roller Type |

| 7 | Compression Width | mm | 1400 |

| 8 | Compression Diameter | mm | Φ 1200 |

| 9 | Number of Compression Working Parts | Units | 18 (Roller) |

| 10 | Compression Roller Diameter | mm | Φ 222 |

| 11 | Bale Tying Method | / | Net Wrap |

| 12 | Matching Power | kW | 55–100 |

| 13 | Structural Mass | kg | 4312 |

| 14 | Power Output Shaft Speed | r/min | 720 |

| 15 | Overall Dimensions (L × W × H) (Working State) | mm | 4470 × 3010 × 2370 |

| 16 | Bale Density Control | / | Sensor Control |

| 17 | Bale Dimensions (Diameter × Width) | mm | Φ 1300 × 1400 |

| 18 | Bale Density | Kg/m³ | 100–200 |

| 19 | Productivity | Bales/h | 40–100 |

| 20 | Wheelbase | mm | 2600 |

| 21 | Working Speed | Km/h | 5–35 |

| 22 | Net Wrap Specification (L × W) | / | 2000 × 1.4 m/bale |

| 23 | Compatible Tractor Models | / | John Deere 5E Series, Case IH Farmall, Massey Ferguson 4700 Series (or equivalent 55-100 kW tractors) |

| 24 | Hydraulic Requirements | / | Standard 2-3 hydraulic outlets, 2000-3000 PSI |

| 25 | Tire Size | / | 15/55-17 (rear), 11L-15 (front) |

| 26 | Electrical System | V | 12V DC with tractor battery connection |

| 27 | Warranty Period | Years | 2 (structural), 1 (components) |

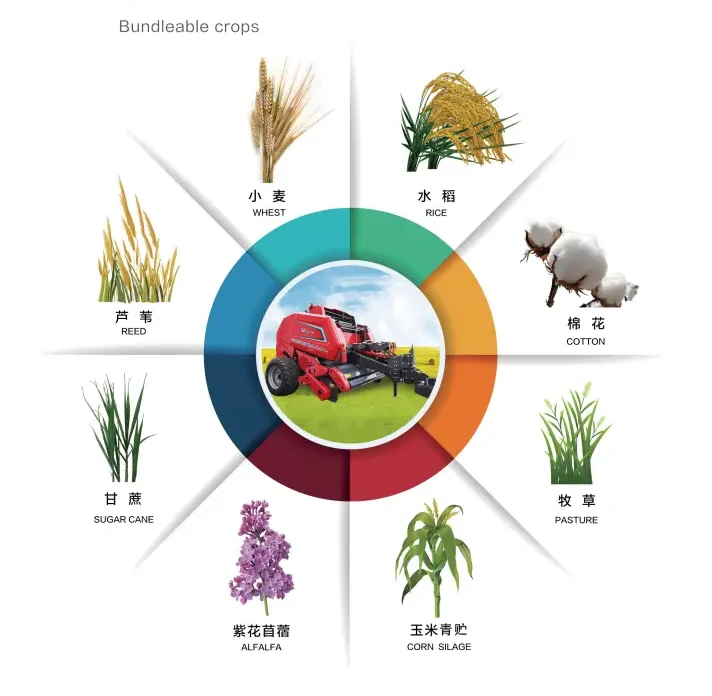

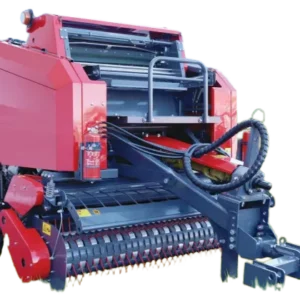

Introduction to the 9YG-2.24D Round Hay Baler

The 9YG-2.24D Round Hay Baler, known as the S9000 Classic model, is a sophisticated piece of agricultural equipment engineered for optimal forage processing. As a high-density round baler, it excels in transforming loose crop residues into tightly packed cylindrical bales, facilitating easier handling and preservation. Manufactured by Netherlands Square Baler Co., Ltd., a renowned round hay baler manufacturer, this towed machine features a pickup width of 2240 mm, allowing extensive field coverage in a single pass. The tine-type pickup structure gently collects materials, while the fork and roller feeding mechanism ensures consistent flow into the compression chamber. With a compression width of 1400 mm and diameter up to 1200 mm, it produces bales of Φ1300 × 1400 mm dimensions, achieving densities from 100 to 200 Kg/m³ through sensor control. This net wrap baler utilizes a roller-type compression with 18 rollers of Φ222 mm diameter, tied securely with net wrap specifications of 2000 × 1.4 m per bale. Requiring 55–100 kW matching power and operating at 720 r/min PTO speed, it delivers productivity of 40–100 bales per hour at speeds of 5–35 Km/h. The structural mass of 4312 kg and wheelbase of 2600 mm provide stability, with overall dimensions of 4470 × 3010 × 2370 mm in working state.

Advanced Traction and Hydraulic Systems

The traction device incorporates a proprietary double cross-joint drive shaft with added safety torque protection, safeguarding components and resolving issues like drive shaft jamming during tight turns in small plots for towed balers. This design enhances flexibility, reducing turning radius and allowing continuous power transmission via the gearbox, boosting efficiency. The rigid connection between the dual-linked gearbox and traction frame ensures stability on uneven terrain, preventing damage. As a durable towed baler, it adapts to high-low undulations without compromising integrity. The hydraulic system employs H-type ferrule joints for increased pressure capacity, accelerating chamber opening and closing. A buffer cylinder on the rear chamber mitigates vibration-induced damage, while the heavy-duty gearbox amplifies transmission torque. Dual-side sprocket drive on the rear chamber promotes smoother, more efficient baling. Compatible tractor models include John Deere 5E Series, Case IH Farmall, and Massey Ferguson 4700 Series, which align with the 55-100 kW power range. Hydraulic needs standard 2-3 outlets at 2000-3000 PSI, and the 12V DC electrical system connects seamlessly to tractor batteries. Tire sizes of 15/55-17 rear and 11L-15 front offer robust traction.

Product Features and Functionality

This forage baler boasts innovative features like quick hitching, where the flexible traction frame rotation enables smooth pin connections, minimizing setup time. The dual gearbox’s 90-degree rotation capability improves maneuverability without power interruption, ideal for field turns. As a sensor-controlled bale density machine, it allows precise adjustments for crop types, ensuring optimal compression. The net wrap method protects bales from environmental factors, preserving quality. Functionality extends to high-speed operations, with productivity peaking under ideal conditions. Details such as the 18 compression rollers ensure even pressure distribution, while the buffer cylinder enhances longevity. In application areas, it serves livestock feed preparation, crop residue management, and biofuel production. Qualifications include ISO9001 certification for quality assurance and patents for the drive shaft and hydraulic innovations, underscoring reliability as a round baler supplier.

Case Studies in Real-World Applications

In a North American alfalfa farm, the 9YG-2.24D Round Hay Baler integrated with a 80 kW John Deere tractor achieved 70 bales per hour at 150 Kg/m³ density, reducing storage needs by 20% and improving feed quality through uniform wrapping. Another case in European pastures involved pairing with mowers for grass hay, where the towed design and dual gearbox facilitated efficient turns on hilly terrain, increasing daily output by 18%. In Asian rice fields, adapted for straw, the machine’s sensor control maintained consistency in humid conditions, supporting biofuel initiatives with minimal waste.

Exploring Technical Parameters and Tractor Compatibility

The parameters of the 9YG-2.24D highlight its engineering prowess. The 2240 mm pickup width and tine structure maximize intake, while the fork and roller feeding ensures clog-free operation. Compression via 18 rollers at Φ222 mm diameter yields high-density bales, controlled by sensors for 100–200 Kg/m³. Net wrap at 2000 × 1.4 m secures output, with productivity up to 100 bales/h. The 4312 kg mass and 2600 mm wheelbase provide balance, aided by tire configurations. For tractor compatibility, the 55–100 kW range suits models like Case IH Farmall, which offer reliable towing at 720 r/min PTO. Massey Ferguson 4700 Series excels in hydraulic integration, supporting the 2-3 outlets at 2000-3000 PSI. The 12V system ensures electrical harmony, making this a versatile buy round hay baler option.

Innovations in Design and Performance

Innovative elements include the safety torque drive shaft, protecting against overloads during turns, and the H-type hydraulic joints for faster chamber actions. The buffer cylinder absorbs vibrations, while the heavy-duty gearbox and dual sprocket drive ensure smooth baling. As a best round hay baler for tractor, it resolves jamming in small plots, enhancing efficiency. Functionality covers rapid hitching and continuous power, ideal for high-low terrain. Details like the 1400 mm compression width optimize material use, with bale dimensions suited for standard transport.

Application Domains and Qualifications

In livestock sectors, it preserves feed value; in crop management, it recycles residues. For alfalfa, uniform density maintains nutrition across climates. Qualifications feature patents for traction and hydraulics, plus export certifications. As a high-density round hay baler for alfalfa, it supports sustainable practices, reducing waste. The warranty of 2 years structural and 1 year components assures longevity.

Extending Operational Insights

Working at 5–35 Km/h, it adapts to field paces, with dimensions allowing easy maneuvering. The electrical and hydraulic specs ensure compatibility, while innovations like the gearbox boost torque. In diverse applications, from biofuel to bedding, its versatility shines. As a durable towed baler for small fields, it minimizes labor through efficient design.

Performance Enhancements and Maintenance

Enhancements include vibration reduction for durability, and sensor precision for density. Maintenance is simplified with accessible parts, supported by our round baler supplier network. In qualifications, AAA credit reflects reliability. For hay baler for sale, its features promise value.

About Netherlands Square Baler Co., Ltd. and Our Diverse Product Portfolio

Netherlands Square Baler Co., Ltd. is a trusted hay baler manufacturer dedicated to innovative agricultural solutions. With a expansive 40,000-square-meter facility and over 260 skilled professionals, we leverage more than 200 advanced tools to produce certified equipment. Holding ISO9001, AAA credit, and multiple patents, our expertise spans beyond this high-density round hay baler to include mowers for field preparation, rakes for material gathering, square balers for alternative shapes, kidney bean pullers for crop-specific harvesting, round bale pickup and transport vehicles for logistics, and feed crushers for nutrition processing. As a comprehensive agricultural baler supplier, we emphasize durability, affordability, and global adaptability.

User Feedback from Around the World

- From New York: “This round hay baler fits my tractor okay, handles alfalfa with decent density, though turns in small fields take some getting used to.”

- From Berlin: “The high-density round baler does uniform wheat straw bales; maintenance is straightforward, but net wrap setup could be quicker in wet weather.”

- From Rio de Janeiro: “Using this durable towed baler for corn stalks works fine with my rakes; it’s stable on uneven ground, though humidity affects speed sometimes.”

- From Sydney: “The affordable round baler makes tight grass hay bales; variable chamber helps with different sizes, but dust buildup requires regular cleaning.”

- From Johannesburg: “This sensor-controlled bale density machine compresses forage evenly for feed; pairs well with crushers, but spare parts delivery takes time here.”